Akta Pure 25 Error in Order to Continue the Filled Tubes Have to Be Replaced

- FAQ

- Troubleshooting

- Accessories

- Flow path schemes

- Spare parts

FAQ

Why should I have REGULAR, PLANNED MAINTENANCE on my system?

Why should I have REGULAR, PLANNED MAINTENANCE on my system?

With the pressure on producing sample or results, the condition of your ÄKTAdesign or Ettan system is critical and regular servicing will mean you can depend on your system to perform as expected. Planned maintenance can be part of a service agreement, scheduled to service your system before it is in need of attention. We can help you design a schedule and routine to allow you to maintain your system, please contact your local Cytiva service representative.

So what can you expect from a planned maintenance visit from Cytiva service representative?

- Thorough inspection and cleaning of system components

- Update of system firmware to ensure full compatibility of your system and UNICORN software

- Replacement of damaged or corroded seals, valve springs and solenoids

- Replacement of items that are reaching the end of their expected life – preventing future breakdowns

- Advice and guidance on proper daily use, cleaning and care of your system

- All work is documented and reported to help make any regulatory audits easier.

A complete overhaul, once a year, ensures that your instrument is running at peak performance so you can be confident of your scientific results. In addition, wear and tear on systems under constant use by multiple end users is minimized, giving the system a longer life and better value for money.

To find out more about service possibilities contact your local Cytiva service representative.

Which EMPTY COLUMNS are recommended for my ÄKTA pure system?

Tricorn 5, High Performance Column

Tricorn 10, High Performance Column

HiScale 16

HiScale 26

HiScale 50

XK 16

XK 26

XK 50

I want to know the FLOW and PRESSURE RANGE of my system?

I want to know the FLOW and PRESSURE RANGE of my system.

| System | Height (mm) | Footprint (mm x mm) | Weight (kg) | Flow rate (ml/min) | Pressure limit (MPa) |

|---|---|---|---|---|---|

| ÄKTA avant 25 | 660 | 860 x 710 | 116 | 0.001-25 | 20 |

| ÄKTA avant 150 | 660 | 860 x 710 | 116 | 0.001-150 (normal range) 0.001-300 (column packing flow) | 5 |

| ÄKTA pure | 630 | 535 x 470 | up to 53 kg | 0.001 to 25 (up to 50 during column packing) | 20 |

| ÄKTA pure 150 | 630 | 535 x 470 | up to 53 kg | 0.01 to 25 (up to 300 during column packing) | 5 |

| ÄKTAexplorer 10 | 620 | 500 x 460 | 75 | 0.001-10 | 25 |

| ÄKTAexplorer 100 | 620 | 500 x 460 | 75 | 0.01-100 | 10 |

| ÄKTAFPLC | 470 | 380 x 480 | 50 | 0.05-20 | 5 |

| ÄKTAmicro | 610 | 480 x 450 | 55 | 0.001-2 | 35 |

| ÄKTApilot | 900 | 750 x 540 | 114 | 4-400 (full gradients) 4-800 (limited gradients) | 2 |

| ÄKTAprime plus | 530 | 400 x 450 | 13 | 0.1-50 | 1 |

| ÄKTApurifier 10 | 620 | 500 x 460 | 75 | 0.001-10 | 25 |

| ÄKTApurifier 100 | 620 | 500 x 460 | 75 | 0.01-100 | 10 |

| ÄKTAxpress | 660 | 490 x 250 | 30 | 0.1-65 | 3 |

| Ettan LC | 610 | 480 x 450 | 55 | 0.001-2 | 35 |

| Ettan MDLC | 710 | 700 x 640 | 105 | 0.001-2 | 35 |

| Ettan microLC | 1150 | 650 x 500 | 77 | 0.001-2 | 35 |

| Ettan nanoLC | 1150 | 650 x 500 | 77 | 0.001-2 | 35 |

I want to know the DIMENSIONS and WEIGHT of my system.

I want to know the DIMENSIONS and WEIGHT of my system.

| System | Height (mm) | Footprint (mm x mm) | Weight (kg) | Flow rate (ml/min) | Pressure limit (MPa) |

|---|---|---|---|---|---|

| ÄKTA avant 25 | 660 | 860 x 710 | 116 | 0.001-25 | 20 |

| ÄKTA avant 150 | 660 | 860 x 710 | 116 | 0.001-150 (normal range) 0.001-300 (column packing flow) | 5 |

| ÄKTA pure | 630 | 535 x 470 | up to 53 kg | 0.001 to 25 (up to 50 during column packing) | 20 |

| ÄKTA pure 150 | 630 | 535 x 470 | up to 53 kg | 0.01 to 150 (up to 300 during column packing) | 5 |

| ÄKTAexplorer 10 | 620 | 500 x 460 | 75 | 0.001-10 | 25 |

| ÄKTAexplorer 100 | 620 | 500 x 460 | 75 | 0.01-100 | 10 |

| ÄKTAFPLC | 470 | 380 x 480 | 50 | 0.05-20 | 5 |

| ÄKTAmicro | 610 | 480 x 450 | 55 | 0.001-2 | 35 |

| ÄKTApilot | 900 | 750 x 540 | 114 | 4-400 (full gradients) 4-800 (limited gradients) | 2 |

| ÄKTAprime plus | 530 | 400 x 450 | 13 | 0.1-50 | 1 |

| ÄKTApurifier 10 | 620 | 500 x 460 | 75 | 0.001-10 | 25 |

| ÄKTApurifier 100 | 620 | 500 x 460 | 75 | 0.01-100 | 10 |

| ÄKTAxpress | 660 | 490 x 250 | 30 | 0.1-65 | 3 |

| Ettan LC | 610 | 480 x 450 | 55 | 0.001-2 | 35 |

| Ettan MDLC | 710 | 700 x 640 | 105 | 0.001-2 | 35 |

| Ettan microLC | 1150 | 650 x 500 | 77 | 0.001-2 | 35 |

| Ettan nanoLC | 1150 | 650 x 500 | 77 | 0.001-2 | 35 |

What DOCUMENTS are supplied with the ÄKTA pure system?

ÄKTA pure Operating Instructions (English), printed copy

ÄKTA pure Product Documentation (material specification and EC declaration of conformance)

Documentation CD: Translated versions of Operating Instructions (PDF) and ÄKTA pure System Handbook (PDF)

Instrument configuration CD

How can I USE my system in COLD ROOMS?

How can I use my system in cold rooms?

Purifying some samples at room temperature can lead to increased levels of degradation; performing your purifications at 4C can help. All our ÄKTA systems, Ettan LC, Ettan microLC, Ettan nanoLC and fraction collectors are suitable for use in the temperature range of 4-40C.

The computer systems are not however cold room compatible, and can be damaged by being placed at 4C.

When installing an ÄKTA system in a cold room the computer can be positioned up to 15 m away, allowing it to be positioned outside the cold room. Cold cabinets can provide an effective solution to running your ÂKTA system in the cold whilst protecting the PC. When moving a system to or from a cold room, time must be allowed for the system to adjust to its new temperature. You may also find that you need to tighten the connectors on your system slightly to prevent leaks when you bring a system out from the cold, and loosen them slightly before you put a system into the cold to prevent pressure build up.

Changes in temperature can also affect the viscosity of your buffers so keep a close eye on your back pressure.

Chemical resistance guide and chemical compatibility

This section specifies the chemical resistance of ÄKTA pure to some of the most commonly used chemicals in liquid chromatography.

Assumptions made

The ratings are based on the following assumptions:

- Synergy effects of chemical mixtures have not been taken into account.

- Room temperature and limited overpressure is assumed.

Chemical influences are time and pressure dependent. Unless otherwise stated, all concentrations are 100%.

List of chemicals

Proposed chemical compatibility for ÄKTA pure. All chemicals used for CIP and cleaning are for short term use only, ambient temperature < 25ºC, if not other stated.

Note : A user can be exposed to large volumes of chemical substances over a long time period. A Material Safety Data Sheet (MSDS) provides the user with information regarding characteristics, human and environmental risks and preventive measures. Make sure that you have the MSDS available from your chemical distributor and/or databases on the internet.

| Chemical | Concentration | CAS no/ EC no |

|---|---|---|

| Aqueous buffers, pH 2-12 | - | N/A |

| Acetic acid | 70% | 64-19-7/ 200-580-7 |

| Acetonitrile1 Depending on pressure, tubing between pump head and pressure monitor needs to be changed. See ÄKTA pure System Handbook, chapter Prepare the system for a run. | 100% | 75-05-8/ 200-835-2 |

| Acetonitrile/Tetrahydrofuran (THF) | 85/15 | 109-99-9/ 203-726-8 |

| Acetone | 10% | 67-64-1/ 200-662-2 |

| Ammonia | 30% | 7664-41-7/ 231-635-3 |

| Ammonium chloride | 2 M | 12125-02-9/ 235-186-4 |

| Ammonium sulphate | 3 M | 7783-20-2/ 231-984-1 |

| Arginine | 2 M | 74-79-3/ 200-811-1 |

| Benzyl alcohol | 2% | 100-51-6/ 202-859-9 |

| Decon™ 90 | 10% | N/A |

| Dimethyl sulphoxide (DMSO) | 5% | 67-68-5/ 200-664-3 |

| Dithiothreitol (DTT) | 100 mM | 3483-12-3 / 222-468-7 |

| Dithioerythritol (DTE) | 100 mM | 6892-68-8/ 229-998-8 |

| Ethylenediaminetetraaceticacid (EDTA) | 100 mM | 60-00-4/ 200-449-4 |

| Ethanol | 20% | 75-08-1/ 200-837-3 |

| Ethanol | 96% | 75-08-1/ 200-837-3 |

| Ethanol + NaOH | 40% + 1 M | N/A |

| Ethylene glycol | 50% | 107-21-1/ 203-473-3 |

| Formic acid | 1% | 64-18-6/ 200-579-1 |

| Glycerol | 50% | 56-81-5/ 200-289-5 |

| Glycine | 2 M | 56-40-6/ 200-272-2 |

| Guanidinium hydrochloride | 6 M | 50-01-1/ 200-002-3 |

| Hydrochloric acid2 | max. 0.1 M | 7647-01-0/ 231-595-7 |

| Imidazole | 2 M | 288-32-4/ 206-019-2 |

| Isopropanol | 100% | 67-63-0/ 200-661-7 |

| Methanol | 100% | 74-93-1/ 200-659-6 |

| Mercaptoethanol | 20 mM | 37482-11-4/ 253-523-3 |

| n-Propanol | 50% | 67-63-0/ 200-661-7 |

| Phosphoric acid | 0.1 M | 7664-38-2/ 231-633-2 |

| Potassium phosphate | 1 M | 7778-77-0/ 231-913-4 |

| Potassium chloride | 4 M | 7447-40-7/ 231-211-8 |

| Sodium dodecyl sulfate (SDS) | 1% | 151-21-3/ 205-788-1 |

| Sodium chloride | 4 M | 7647-14-5/ 231-598-3 |

| Sodium hydroxide | 2 M | 1310-73-2/ 215-185-5 |

| Sodium sulphate | 1 M | 7757-82-6/ 231-820-9 |

| Trichloroacetic acid | 1% | 76-03-9/ 200-927-2 |

| Trifluoroacetic acid | 1% | 176-05-1/ 200-929-3 |

| Triton™ X-100 | 1% | 9002-93-1 |

| Tween 20 | 1% | 9005-64-5/ 500-018-3 |

| Urea | 8 M | 57-13-6/ 200-315-5 |

| Water | 100% | 7732-18-5/ 231-791-2 |

1 PEEK tubing is biocompatible and chemically inert to most solvents used in the purification of proteins. It has in general very good pressure limits, especially for water based buffers. However, organic solvents can penetrate weaknesses in the tubing walls more easily than water based buffers. Special care should therefore be taken with prolonged use of organic solvents close to pressure limits.

2 If hydrochloric acid, HCl, is used as a cleaning agent when columns are connected to the system, the HCl concentration should not exceed 0.1 M in the System pressure monitor or in the pressure monitor in Column valve V9-C.

For other parts of the system up to 1 M HCl is acceptable for short time use.

For cleaning of columns with HCl concentrations exceeding 0.1 M, manually fill a loop with HCl and inject the cleaning agent.

Spare parts

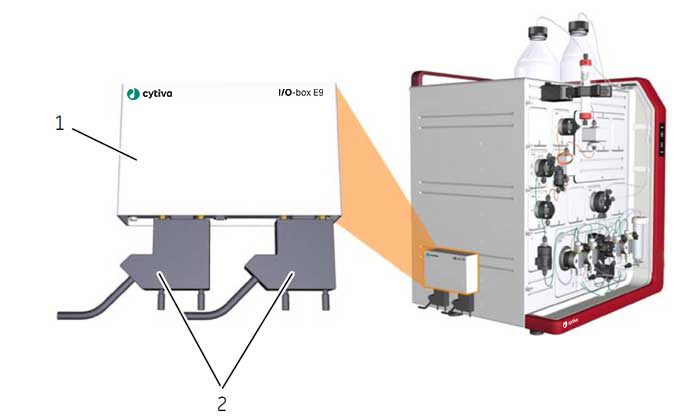

I/O box

Location of the I/O box

The illustration below shows the I/O-box and its recommended location and connection points.

Function of the I/O-box

The I/O-box E9 is used to interface other equipment in order to measure parameters such as refractive index, light scattering and fluorescence. See Requirements on connected equipment, on page 196 for information on requirements of the equipment that can be connected to ÄKTA pure. The I/O-box can control external equipment by a digital output signal, as well as detecting the state of them by digital inputs. It is possible to install up to two I/O-box E9 when using ÄKTA pure. If two I/O-boxes are to be used, the second one has to be configured as I/O-box E9, 2nd. The configuration is defined by the I/O-box E9 Node ID.

| Part | Description |

|---|---|

| 1 | I/O-box |

| 2 | D-sub connectors |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

Module components

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

Cables

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

Tubing, unions, ferrules and stop plugs for ÄKTA pure

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

| # | Product Name | Product Code | Price | |

|---|---|---|---|---|

| Inlet filter holder kit | 11000407 | 154.21 USD | Add to cart Get Quote | |

| Inlet filter set | 11000414 | 100.83 USD | Add to cart Get Quote | |

| Tubing cutter, for PEEK, EFTE, and FEP tubing i.d. 0.25, 0.5, 0.75, 1 and 1.6 mm | 18111246 | 80.74 USD | Add to cart Get Quote | |

| Reference capillary 1 | 28950749 | 111.09 USD | Add to cart Get Quote | |

| Reference capillary 2 | 28950750 | 111.09 USD | Add to cart Get Quote | |

| Union 1/16 male/male, i.d. 0.5 mm | 28954326 | 151.54 USD | Add to cart Get Quote | |

| ETFE Tubing Kit 10 x 1.0 m, i.d. 1.0 mm, o.d. 1/16" | 28980995 | 185.87 USD | Add to cart Get Quote | |

| Tubing Kit, 0.50 mm | 29011327 | 1 052.00 USD | Add to cart Get Quote | |

| Tubing Kit, 0.25 mm | 29011328 | 1 054.00 USD | Add to cart Get Quote | |

| Tubing Kit, 0.75 mm | 29011329 | 1 052.00 USD | Add to cart Get Quote | |

| Tubing kit for inlet valve V9-IAB | 29011330 | 274.00 USD | Add to cart Get Quote | |

| Tubing kit for V9-pH, standard | 29011331 | 262.00 USD | Add to cart Get Quote | |

| Tubing kit for V9-IA (7-ports) | 29011332 | 285.00 USD | Add to cart Get Quote | |

| Tubing kit for V9-IB (7-ports) | 29011333 | 284.00 USD | Add to cart Get Quote | |

| Tubing kit for outlet fractionation (10 outlets) | 29011334 | 255.00 USD | Add to cart Get Quote | |

| System Pump Rinse Tubing Kit | 29011348 | 129.29 USD | Add to cart Get Quote | |

| Tubing Kit i.d. 1.0 mm | 29032426 | 1 074.00 USD | Add to cart Get Quote | |

| Tubing kit for Sample Inlet Valve V9-IS | 29035331 | 284.00 USD | Add to cart Get Quote | |

| System Tubing kit for ÄKTA pure 150, i.d. 0.75 mm | 29048242 | 1 054.00 USD | Add to cart Get Quote | |

| Tubing Kit for Outlet Fractionation (10 outlets) | 29048611 | 255.00 USD | Add to cart Get Quote | |

| Tubing kit for Sample Inlet Valve V9H-IS | 29051166 | 284.00 USD | Add to cart Get Quote | |

| Tubing kit for V9H-IB (7-ports) | 29051189 | 284.00 USD | Add to cart Get Quote | |

| Tubing kit for V9H-IA (7-ports) | 29051197 | 284.00 USD | Add to cart Get Quote | |

| System Tubing kit for ÄKTA pure 150, i.d. 0.50 mm | 29051669 | 1 052.00 USD | Add to cart Get Quote | |

| V9H-pH Tubing Kit | 29051674 | 254.00 USD | Add to cart Get Quote |

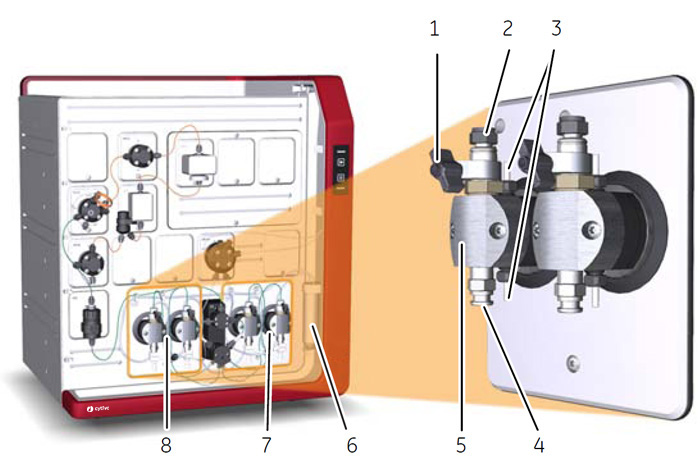

System Pumps and Sample pump S9H

Location and illustration of pumps

The illustration below shows the location of System pump A and System pump B, together with a detailed view of a system pump. System pump A is labeled P9 A and System pump B is labeled P9 B.

| Part | Description |

|---|---|

| 1 | Purge valve: Used to remove air from the pump |

| 2 | Outlet port with check valve |

| 3 | Connections to pump piston rinsing system: Tubing is connected between the pumps and the Pump piston rinsing system tube (6) |

| 4 | Inlet port with check valve |

| 5 | Pump head: Encapsulates the inner parts of the pump |

| 6 | Pump piston rinsing system tube |

| 7 | System pump B |

| 8 | System pump A |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

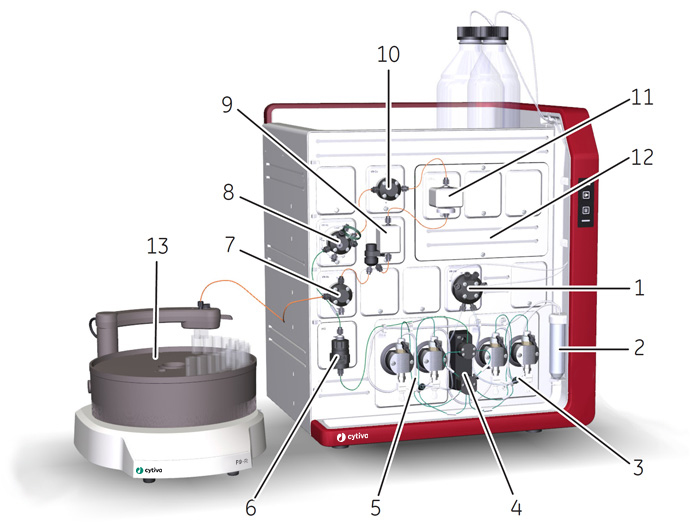

Illustration of typical configuration

Typical configuration of an ÄKTA pure 25 (25 ml/min) system.

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

| # | Product Name | Product Code | Price | |

|---|---|---|---|---|

| 1 | Inlet Valve Kit V9-IA | 29012263 | 6 025.00 USD | Add to cart Get Quote |

| 3 | Check valve kit | 18112866 | 1 134.00 USD | Add to cart Get Quote |

| 3 | P9 Seal kit, 25 ml | 28952642 | 562.00 USD | Add to cart Get Quote |

| 5 | Check valve kit | 18112866 | 1 134.00 USD | Add to cart Get Quote |

| 5 | Piston kit, 25 ml | 28952640 | 758.00 USD | Add to cart Get Quote |

| 5 | P9 Seal kit, 25 ml | 28952642 | 562.00 USD | Add to cart Get Quote |

| 6 | Online filter kit | 18102711 | 132.86 USD | Add to cart Get Quote |

| 6 | O-ring 13.1x1.6 mm | 28953545 | 70.52 USD | Add to cart Get Quote |

| 6 | Mixer chamber 0.6 ml | 28956186 | 1 247.00 USD | Add to cart Get Quote |

| 6 | Mixer chamber 1.4 ml | 28956225 | 1 261.00 USD | Add to cart Get Quote |

| 6 | Mixer chamber 5 ml | 28956246 | 1 261.00 USD | Add to cart Get Quote |

| 6 | O-ring 13.1 x 1.6 mm High resistance | 29011326 | 188.23 USD | Add to cart Get Quote |

| 6 | Outlet Valve Kit V9-Os | 29011356 | 2 329.00 USD | Add to cart Get Quote |

| 7 | Outlet valve kit V9-O | 29012261 | 3 971.00 USD | Add to cart Get Quote |

| 8 | Injection Valve V9-Inj | 28956514 | 3 744.00 USD | Add to cart Get Quote |

| 9 | Conductivity monitor (C9n) | 29011363 | 2 677.00 USD | Add to cart Get Quote |

| 10 | Column Valve V9-Cs | 29011355 | 3 422.00 USD | Add to cart Get Quote |

| 10 | Column Valve kit V9-C | 29011367 | 8 076.00 USD | Add to cart Get Quote |

| 11 | UV flow cell, 5 mm, for U9-L | 18112824 | 2 166.00 USD | Add to cart Get Quote |

| 11 | UV flow cell, 10 mm, for U9-M | 28956378 | 2 186.00 USD | Add to cart Get Quote |

| 11 | UV flow cell, 2 mm, for U9-M | 28979380 | 3 249.00 USD | Add to cart Get Quote |

| 11 | UV flow cell, 0.5 mm, for U9-M | 28979386 | 3 374.00 USD | Add to cart Get Quote |

| 11 | UV flow cell, 2 mm, for U9-L | 29011325 | 2 609.00 USD | Add to cart Get Quote |

| 11 | UV Monitor U9-L | 29011360 | 5 493.00 USD | Add to cart Get Quote |

| 12 | Multi-module panel | 29011351 | 670.00 USD | Add to cart Get Quote |

| 13 | Tube Rack 40 × 30 mm, bowl, tube support, holder and guide | 18112467 | 560.00 USD | Add to cart Get Quote |

| 13 | Tube Holder and Guide, 40 × 30 mm | 18112468 | 465.00 USD | Add to cart Get Quote |

| 13 | Tube Rack Complete, 95 × 10–18 mm | 18305003 | 627.00 USD | Add to cart Get Quote |

| 13 | Bowl | 18305103 | 166.52 USD | Add to cart Get Quote |

| 13 | Tube Support | 18305402 | 142.07 USD | Add to cart Get Quote |

| 13 | Tubing Holder | 18646401 | 91.33 USD | Add to cart Get Quote |

| 13 | Drive sleeve | 19606702 | 108.13 USD | Add to cart Get Quote |

| 13 | Tube Holder and Guide, 175 × 12 mm | 19724202 | 386.00 USD | Add to cart Get Quote |

| 13 | Tube Rack 175 × 12 mm, bowl, tube support, holder and guide | 19868403 | 454.00 USD | Add to cart Get Quote |

| 13 | Tube Holder and Guide, 95 × 10–18 mm | 19868902 | 253.00 USD | Add to cart Get Quote |

| 13 | Fraction Collector F9-R | 29011362 | 3 892.00 USD | Add to cart Get Quote |

Accessories

Holders for ÄKTA pure

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

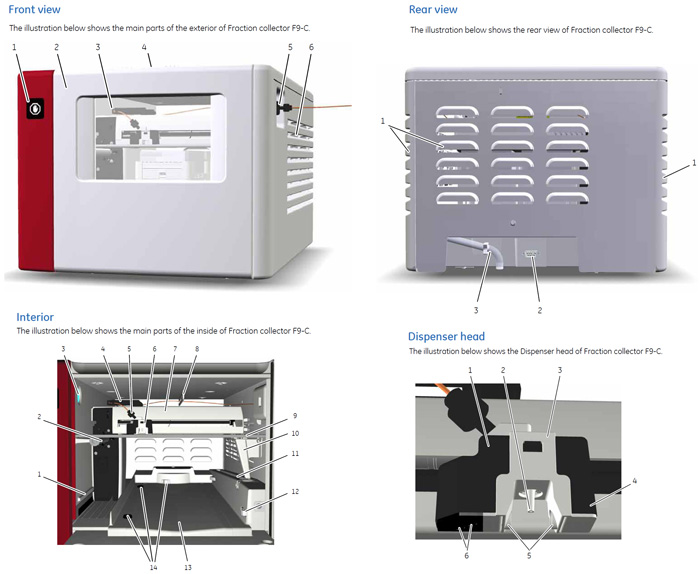

Fraction collector F9-C

Front view

| Part | Description |

|---|---|

| 1 | Fractionation indicator Symbol indicating that fractionation is ongoing. Do not open the door while the indicator is lit. |

| 2 | Door |

| 3 | Window |

| 4 | Door handle |

| 5 | Tubing connector for outlet valve tubing |

| 6 | Vents |

Rear view

| Part | Description |

|---|---|

| 1 | Vents |

| 2 | UniNet-9 D-type connector (for communication and power supply) |

| 3 | Waste tube |

Interior

| Part | Description |

|---|---|

| 1 | Fractionation arm guide rail |

| 2 | Fractionation arm main rail |

| 3 | Lamp |

| 4 | Tubing guide |

| 5 | Tubing connection |

| 6 | Dispenser head |

| 7 | Fractionation arm |

| 8 | Tubing guide |

| 9 | Height exclusion bar |

| 10 | Waste funnel |

| 11 | Waste tube |

| 12 | Tray catch |

| 13 | Waste groove, in case of overflow |

| 14 | Tray guides |

Dispenser head

| Part | Description |

|---|---|

| 1 | Dispenser head |

| 2 | Nozzle |

| 3 | Dispenser head cover |

| 4 | Accumulator (back part of Dispenser head) |

| 5 | Drop sync sensor |

| 6 | Type code reader |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

| # | Product Name | Product Code | Price | |

|---|---|---|---|---|

| UNIPLATE Collection and Analysis Microplate, 24-well, 10 ml, natural polypropylene, round well bottom | 28420867 | 288.00 USD | Add to cart Get Quote | |

| UNIPLATE Collection and Analysis Microplate, 96-well, 2 ml, natural polypropylene, round well bottom | 28420869 | 229.00 USD | Add to cart Get Quote | |

| UNIPLATE Collection and Analysis Microplate, 48-well, 5 ml, natural polypropylene, rectangular well, flat bottom | 28420874 | 295.00 USD | Add to cart Get Quote | |

| Cassette tray | 28954209 | 286.00 USD | Add to cart Get Quote | |

| Cassette for fraction collection in deep-well plate | 28954212 | 178.76 USD | Add to cart Get Quote | |

| Cassette for 50 ml tubes | 28956402 | 182.31 USD | Add to cart Get Quote | |

| Cassette, for 15 ml tubes | 28956404 | 182.31 USD | Add to cart Get Quote | |

| Cassette for fraction collection in 8 mL tubes | 28956425 | 182.68 USD | Add to cart Get Quote | |

| Cassette, for 3 ml tubes | 28956427 | 182.68 USD | Add to cart Get Quote | |

| Rack, for 50 ml tubes | 28980319 | 712.00 USD | Add to cart Get Quote | |

| Rack for fraction collection in 250 mL bottles | 28981873 | 1 528.00 USD | Add to cart Get Quote | |

| Fraction Collector F9-C | 29027743 | 11 600.00 USD | Add to cart Get Quote | |

| Cable 2.5m UniNet-9 D-type | 29032425 | 129.29 USD | Add to cart Get Quote |

Injection valve accessories

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

| # | Product Name | Product Code | Price | |

|---|---|---|---|---|

| Superloop Complete, 150 ml, M6 fitting | 18102385 | 1 494.00 USD | Add to cart Get Quote | |

| Injection Kit, INV-907 | 18111089 | 580.00 USD | Add to cart Get Quote | |

| Superloop, 1/16" fittings (ÄKTAdesign), 50 ml | 18111382 | 1 253.00 USD | Add to cart Get Quote | |

| Sample loop 100 µl | 18111398 | 172.84 USD | Add to cart Get Quote | |

| Sample loop 500 µl | 18111399 | 224.00 USD | Add to cart Get Quote | |

| Sample loop 1 ml | 18111401 | 188.23 USD | Add to cart Get Quote | |

| Sample Loop 2.0 ml, INV-907 | 18111402 | 280.00 USD | Add to cart Get Quote | |

| Sample loop, 10 µl | 18112039 | 74.73 USD | Add to cart Get Quote | |

| Fill Port, INV-907 | 18112766 | 245.00 USD | Add to cart Get Quote | |

| Sample loop, FEP 10 ml | 18116124 | 174.29 USD | Add to cart Get Quote | |

| Superloop, M6 fitting, 10 ml | 19758501 | 1 720.00 USD | Add to cart Get Quote | |

| Connector 1/16" Male/Luer Female | 28985812 | 834.90 USD | Add to cart Get Quote |

External air sensors

Up to four external air sensors can be added to ÄKTA pure, and there are two different versions to choose from. They differ in internal diameter and optimal position on the instrument.

The air sensors can be attached to the instrument using the rails and holders. No dummy modules need to be removed.

In addition to be used for preventing air from entering the system, the external air sensors can be used together with System pump A to load the entire sample volume.

Air sensor L9-1.5

L9-1.5 has a 1.5 mm inner diameter and is designed for i.d. 1.6 mm FEP tubing at the low pressure side before pumps. It is installed in the flow path before the system pumps and is used to prevent air entering the valve.

Air sensor L9-1.2

L9-1.2 has a 1.2 mm inner diameter and is designed for o.d. 1/16" tubing at the high pressure side after the pumps. It is installed after the injection valve and is used to prevent air entering the column.

Tubing connections

Air sensor L9-1.5

| Connection between | Tubing | Connector |

|---|---|---|

| L9-1.5 and inlet valves | FEP, o.d. 1/8", 1.6 mm | Tubing connector, 5/16" + Ferrule (yellow), 1/8" |

Note: When the air sensor is installed before System pump A, use tubing with a minimum length of 18 cm between the valve located before System pump A and the external air sensor when loading the sample at maximum flow rate, to be sure that air does not reach System pump A. Shorter tubing can be used at lower flow rates.

Air sensor L9-1.2

| Connection between | Tubing | Connector |

|---|---|---|

| V9-Inj and L9-1.2 | PEEK, o.d. 1/16" | Fingertight connector 1/16" |

| L9-1.2 and V9-C/V9-Cs/the connected column | PEEK, o.d. 1/16" | Fingertight connector 1/16" |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

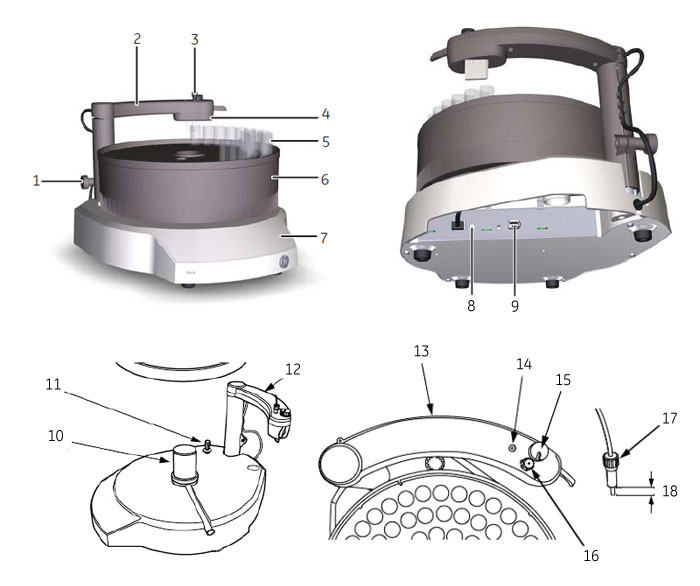

Fraction collector F9-R

Illustration of Fraction collector F9-R, connector panel, base unit and delivery arm.

| Part | Function |

|---|---|

| 1 | Lock knob |

| 2 | Delivery arm |

| 3 | Tubing connector |

| 4 | Tube sensor |

| 5 | Collection tubes |

| 6 | Tube rack |

| 7 | Base unit |

| 8 | Node switch |

| 9 | UniNet-9 communication and power supply |

| 10 | Central spindle |

| 11 | Drive sleeve |

| 12 | Delivery arm |

| 13 | Delivery arm |

| 14 | Tube adjustment cavity |

| 15 | Sensor control |

| 16 | Tubing holder |

| 17 | Tubing holder nut |

| 18 | Exposed tubing end length |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

| # | Product Name | Product Code | Price | |

|---|---|---|---|---|

| Tube Rack 40 × 30 mm, bowl, tube support, holder and guide | 18112467 | 560.00 USD | Add to cart Get Quote | |

| Tube Holder and Guide, 40 × 30 mm | 18112468 | 465.00 USD | Add to cart Get Quote | |

| Tube Rack Complete, 95 × 10–18 mm | 18305003 | 627.00 USD | Add to cart Get Quote | |

| Bowl | 18305103 | 166.52 USD | Add to cart Get Quote | |

| Tube Support | 18305402 | 142.07 USD | Add to cart Get Quote | |

| Tubing Holder | 18646401 | 91.33 USD | Add to cart Get Quote | |

| Drive sleeve | 19606702 | 108.13 USD | Add to cart Get Quote | |

| Tube Holder and Guide, 175 × 12 mm | 19724202 | 386.00 USD | Add to cart Get Quote | |

| Tube Rack 175 × 12 mm, bowl, tube support, holder and guide | 19868403 | 454.00 USD | Add to cart Get Quote | |

| Tube Holder and Guide, 95 × 10–18 mm | 19868902 | 253.00 USD | Add to cart Get Quote | |

| Fraction Collector F9-R | 29011362 | 3 892.00 USD | Add to cart Get Quote |

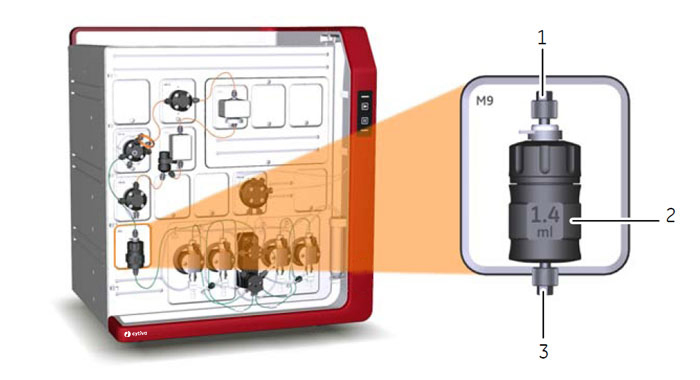

Mixer

The illustration below shows the location, together with a detailed view of Mixer M9.

| Part | Description |

|---|---|

| 1 | Outlet |

| 2 | Mixer chamber |

| 3 | Inlet |

Select Mixer chamber

To obtain a homogeneous buffer composition, it is important to use a Mixer chamber suitable for the flow rate of the method. The tables below show what Mixer chambers to use in ÄKTA pure at different flow rates.

If the liquids are difficult to mix, use a larger Mixer chamber to achieve optimal mixing. However, note that a larger Mixer chamber distorts and delays the gradient.

Three different Mixer chambers are available for ÄKTA pure 25. Their volumes are: 0.6 ml, 1.4 ml (mounted at delivery), and 5 ml.

| Mixer chamber volume [ml] | Flow rate [ml/min], Binary gradient |

|---|---|

| 0.6 | 0.1-5 |

| 1.4 | 0.5-10 |

| 5 | 5-25 |

CAUTION

Risk of explosion. Do not use Mixer chamber 15 ml with an ÄKTA pure 25 configuration.

The maximum pressure for Mixer chamber 15 ml is 5 MPa.

Four different Mixer chambers are available for ÄKTA pure 150. Their volumes are: 0.6 ml, 1.4 ml

(mounted at delivery), 5 ml (included in delivery), and 15 ml.

| Mixer chamber volume [ml] | Flow rate [ml/min], Binary gradient |

|---|---|

| 0.6 | 0.5-5 |

| 1.4 | 0.5-15 |

| 5 | 2-50 |

| 15 | 15-150 |

Note : At low flow rates (below 0.2 ml/min) a gradient of sufficient quality may be achieved with the mixer bypassed.

Note: For the highest flow rates, use the 5 ml mixer for ÄKTA pure 25 and the 15 ml mixer for ÄKTA pure 150. The larger chamber volume minimizes potential pump disturbances.

Note: The 1.4 ml mixer might work up to 25 ml/min provided that the buffers are easily mixed.

Note : O-ring 13.1 x 1.6 mm 28-9535-45 is for use with Mixer chamber 0.6, 1.4 and 5 ml.

Note : O-ring 22.1 x 1.6 mm 28-9818-57 is for use with Mixer chamber 15 ml.

Note : O-ring 13.1 x 1.6 mm 29-0113-26 (high resistant) can be used as an alternative to 29-9535-45.

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

Sample pump S9

ÄKTA pure protein purification system: Sample automation

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

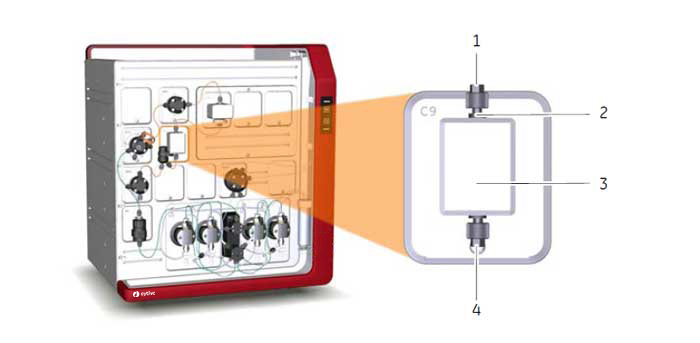

Conductivity monitor

Location and illustration of Conductivity monitor C9n

The illustration below shows the recommended location of Conductivity monitor C9n, together with a detailed view of the monitor. The monitor is labelled C9.

| Part | Description |

|---|---|

| 1 | Inlet |

| 2 | Conductivity flow cell |

| 3 | Conductivity monitor C9n |

| 4 | Outlet |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

| # | Product Name | Product Code | Price | |

|---|---|---|---|---|

| Conductivity monitor (C9n) | 29011363 | 2 677.00 USD | Add to cart Get Quote |

Software

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

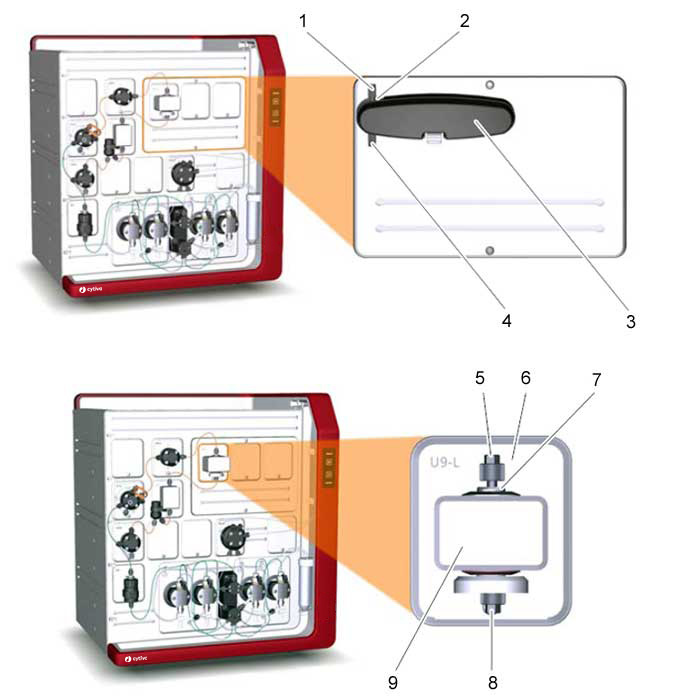

UV monitor and UV flow cells

Location and illustration of UV monitor U9-M and UV monitor U9-L

The illustration below shows the location of UV monitor U9-M, together with a detailed view of the monitor unit and detector. The monitor unit is labelled U9-M and the detector U9-D.

Note: When UV monitor U9-M is used, the entire Multi-module panel shown in the illustration is replaced by U9-M.

The illustration below also shows the recommended location of UV monitor U9-L, together with a detailed view of the monitor and detector. The UV monitor U9-L requires that the Multi-module panel is installed.

| Part | Description |

|---|---|

| 1 | Inlet |

| 2 | UV flow cell. Three different path lengths are available: 0.5 mm, 2 mm (default) and 10 mm |

| 3 | UV detector |

| 4 | Outlet |

| 5 | Inlet |

| 6 | UV monitor U9-L |

| 7 | UV flow cell. Two different path lengths are available: 2 mm (default) and 5 mm |

| 8 | Outlet |

| 9 | UV detector |

Function of UV monitor U9-L

The UV monitor U9-L measures the UV absorbance at the fixed wavelength of 280 nm. It is not possible to vary the wavelength, or turn on or off the U9-L monitor. This is therefore not shown in the Phase Properties pane in Method Editor.

For information on how to install UV monitor U9-L, please refer to Section 4.10 Install UV monitor U9-L, in the system handbook.

Using two UV monitors

The UV monitor U9-L module can be used in two configurations, UV monitor U9-L and UV monitor U9-L, 2nd. The configuration is defined by the module's Node ID.

It is possible to use two UV monitors in ÄKTA pure, in the following combinations:

• UV monitor U9-M together with UV monitor U9-L, 2nd

• UV monitor U9-L together with UV monitor U9-L, 2nd

UV monitor U9-L, 2nd can be located anywhere in the flow path and is therefore shown in the Process Picture as a component without a fixed place. This means that it is possible to place U9-L, 2nd before the other UV monitor in the flow path.

Note: If U9-L, 2nd is placed on the high pressure side of the column, pressure limits have to be considered.

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

| # | Product Name | Product Code | Price | |

|---|---|---|---|---|

| UV flow cell, 5 mm, for U9-L | 18112824 | 2 166.00 USD | Add to cart Get Quote | |

| UV flow cell, 10 mm, for U9-M | 28956378 | 2 186.00 USD | Add to cart Get Quote | |

| UV flow cell, 2 mm, for U9-M | 28979380 | 3 249.00 USD | Add to cart Get Quote | |

| UV flow cell, 0.5 mm, for U9-M | 28979386 | 3 374.00 USD | Add to cart Get Quote | |

| UV flow cell, 2 mm, for U9-L | 29011325 | 2 609.00 USD | Add to cart Get Quote | |

| UV Monitor U9-L | 29011360 | 5 493.00 USD | Add to cart Get Quote |

Valves for ÄKTA pure

The modular design allows the user to customize ÄKTA pure in multiple ways. The system is always delivered with the core modules of the selected configuration, but one or more optional modules may be added to the flow path.

The table below contains information on the core modules and the optional modules of ÄKTA pure 25 and ÄKTA pure 150.

The valves for ÄKTA pure 25 and ÄKTA pure 150 are compatible with both systems but for the best performance the specific valve type should be used.

Note: All valve kits include the necessary tubing.

| Module | Label in ÄKTA pure 25 | Label in ÄKTA pure 150 |

|---|---|---|

| System pump A | P9 A | P9H A |

| System pump B | P9 B | P9H B |

| Pressure monitor | R9 | R9 |

| Mixer | M9 | M9 |

| Injection valve | V9-Inj | V9H-Inj |

| Inlet valve A | V9-IA | V9H-IA |

| Inlet valve B | V9-IB | V9H-IB |

| Inlet valve AB | V9-IAB | V9H-IAB |

| Inlet valve IX | V9-IX | V9H-IX |

| Sample inlet valve | V9-IS | V9H-IS |

| Mixer valve | V9-M | V9H-M |

| Loop valve | V9-L | V9H-L |

| Column valves | V9-C V9-Cs | V9H-C V9H-Cs |

| pH valve | V9-pH | V9H-pH |

| Outlet valves | V9-O V9-Os | V9H-O V9H-Os |

| Versatile valve | V9-V | V9H-V |

| UV monitors | U9-L U9-M | U9-L U9-M |

| Conductivity monitor | C9 | C9 |

| External air sensor | L9-1.5 L9-1.2 | L9-1.5 L9-1.2 |

| Fraction collectors | F9-C F9-R | F9-C F9-R |

| I/O box | E9 | E9 |

| Sample pump | S9 | S9H |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

pH monitor

Location and illustration of the pH monitor

The illustration below shows the location of the pH flow cell and a pH electrode installed in the pH valve.

| Part | Description |

|---|---|

| 1 | pH flow cell |

| 2 | pH electrode |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

Flow path schemes

Flow path scheme for ÄKTA pure

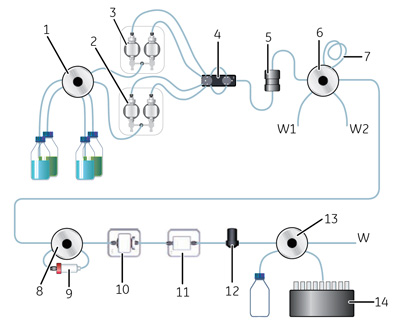

The illustration below shows the flow path for a typical system configuration. The individual instrument modules are presented in the table below. The configuration of the system is defined by the user.

| Part | Description |

|---|---|

| 1 | Inlet valve V9-IAB |

| 2 | System pump B |

| 3 | System pump A |

| 4 | Pressure monitor R9 |

| 5 | Mixer M9 |

| 6 | Injection valve V9-Inj |

| 7 | Capillary loop or Superloop |

| 8 | Column valve V9-Cs |

| 9 | Column |

| 10 | UV monitor U9-L |

| 11 | Conductivity monitor C9n |

| 12 | Flow restrictor |

| 13 | Outlet valve V9-Os |

| 14 | Fraction collector F9-R |

| W, W1, W2 | Waste |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

Description of tubing and connectors for ÄKTA pure

Tubing types

The table below shows the tubing types used in ÄKTA pure.

| Description | Color | Scope of use |

|---|---|---|

| PEEK, o.d. 1/16", i.d. 0.25 mm | Blue | Reference capillary 1 and Tubing Kit 0.25 |

| PEEK, o.d. 1/16", i.d. 0.50 mm | Orange | High pressure tubing |

| PEEK, o.d. 1/16", i.d. 0.75 mm | Green | High pressure tubing |

| FEP, o.d. 1/8", i.d. 1.6 mm | Transparent | Inlet tubing |

| ETFE, o.d. 1/16", i.d. 1.0 mm | Transparent | Outlet and waste tubing |

| Silicon, o.d. 12 mm, i.d. 8 mm | Transparent | Waste tubing from Buffer tray |

Note: Many different sizes/types of tubing can be connected to a chromatography system. Tubing with a smaller inner diameter (i.d.) holds less delay volume and will therefore generate less dilution of the protein peak. Narrow tubing, however, increases the system pressure, especially when running at high flow rates. The tubing used should match the application needs. See Recommended tubing kits, on page 467 in the System Handbook for more information.

Tubing connectors

The table below shows the tubing connectors used in ÄKTA pure.

| Description | Use with tubing... |

|---|---|

| Fingertight connector, 1/16" | • PEEK, o.d. 1/16", i.d. 0.25 mm • PEEK, o.d. 1/16", i.d. 0.50 mm • PEEK, o.d. 1/16", i.d. 0.75 mm • ETFE, o.d. 1/16", i.d. 1 mm |

| Tubing connector 5/16" Ferrule (yellow), 1/8" | FEP, o.d. 1/8", i.d. 1.6 mm |

Other connectors

The table below shows other connectors used in ÄKTA pure.

| Description | Scope of use |

|---|---|

| Stop plug 1/16" | Stop plug for valve parts |

| Luer female | Syringe connector for pH valve and Injection valve |

Tubing labels

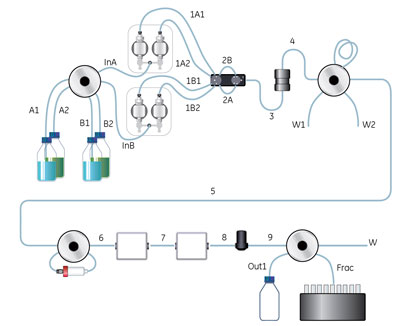

The illustration below shows the tubing labels for for a typical system configuration.

Inlet tubing

The table below shows the labels, diameters, and standard lengths of the inlet tubing.

| Label | Description | Tubing | Length (mm) |

|---|---|---|---|

| A1-A2 and B1-B2 | Inlets to Inlet valve AB | FEP, o.d. 1/8", i.d. 1.6 mm | 1500 |

| A1-A7 | Inlets to Inlet valve A | FEP, o.d. 1/8", i.d. 1.6 mm | 1500 |

| B1-B7 | Inlets to Inlet valve B | FEP, o.d. 1/8", i.d. 1.6 mm | 1500 |

| InA | FromInlet valve A or Inlet valve AB to System pump A | FEP, o.d. 1/8", i.d. 1.6 mm | 220 |

| InB | FromInlet valve B or Inlet valve AB to System pump B | FEP, o.d. 1/8", i.d. 1.6 mm | 220 |

High pressure tubing

The table below shows the labels, diameters, and standard lengths of the high pressure tubing.

| Label | Description | Tubing | Length (mm) |

|---|---|---|---|

| 1A1 | System pump A left to Restrictor A | PEEK, o.d. 1/16", i.d. 0.75 mm | 340 |

| 1A2 | System pump A right to Restrictor A | PEEK, o.d. 1/16", i.d. 0.75 mm | 340 |

| 2A | Restrictor A to Pressure monitor | PEEK, o.d. 1/16", i.d. 0.75 mm | 115 |

| 1B1 | System pump B left to Restrictor B | PEEK, o.d. 1/16", i.d. 0.75 mm | 340 |

| 1B2 | System pump B right to Restrictor B | PEEK, o.d. 1/16", i.d. 0.75 mm | 340 |

| 2B | Restrictor B to Pressure monitor | PEEK, o.d. 1/16", i.d. 0.75 mm | 115 |

| 3 | Pressure monitor to Mixer | PEEK, o.d. 1/16", i.d. 0.75 mm | 400 |

| 4 | Mixer to Injection valve | PEEK, o.d. 1/16", i.d. 0.75 mm | 200 |

| 5 | Injection valve to Column valve | PEEK, o.d. 1/16", i.d. 0.75 mm | 160 |

| 6 | Column valve to UV monitor | PEEK, o.d. 1/16", i.d. 0.75 mm | 160 |

| 7 | UV monitor to Conductivy monitor | PEEK, o.d. 1/16", i.d. 0.75 mm | 170 |

| 8 | Conductivity monitor to Flow restrictor | PEEK, o.d. 1/16", i.d. 0.75 mm | 95 |

| 9 | Flow restrictor to Outlet valve | PEEK, o.d. 1/16", i.d. 0.75 mm | 135 |

| Frac | Outlet valve to Fraction collector | PEEK, o.d. 1/16", i.d. 0.75 mm | 400 |

Reference capillaries

The table below shows the labels, diameters, and standard lengths of the reference capillary. The capillary is used during the System performance tests.

| Label | Description | Tubing | Length (mm) |

|---|---|---|---|

| Ref 1 | Reference capillary | PEEK, o.d. 1/16", i.d. 0.25 mm | 400 |

Outlet tubing

The table below shows the labels, diameters, and standard lengths of the outlet tubing.

The tubing is not mounted on delivery.

| Label | Description | Tubing | Length (mm) |

|---|---|---|---|

| Out1-Out 10 | Outlets from Outlet valve V9-O and Outlet valve V9-Os | ETFE, o.d. 1/8", i.d. 1 mm | 1500 |

Waste tubing

The table below shows the labels, diameters, and standard lengths of the waste tubing. The waste tubing is mounted on delivery.

| Label | Description | Tubing | Length (mm) |

|---|---|---|---|

| W1 | System pump waste | ETFE, o.d. 1/16", i.d. 1.0 mm | 1500 |

| W2 | Sample pump waste | ETFE, o.d. 1/16", i.d. 1.0 mm | 1500 |

| W3 | pH valve waste | ETFE, o.d. 1/16", i.d. 1.0 mm | 1500 |

| W | System waste | ETFE, o.d. 1/16", i.d. 1.0 mm | 1500 |

| N/A | Top tray waste | Silicon, o.d. 12 mm, i.d. 8 mm | 1500 |

Something went wrong - we were not able to load your agreed MSA pricing. Please try refreshing the page.

Troubleshooting

Find solutions to product related issues. For unlisted issues please contact local Cytiva service representation.

Mixer valve

Issues related to the Mixer valve

Outlet valve

Issues related to the Outlet valve

Instrument communication

Issues related to Instrument communication

Cabinet

Issues related to the cabinet

General hardware: All modules

Issues related to general hardware: All modules

Superloop

Issues related to the Superloop

I/O-box E9

Issues related to I/O-box E9

Pumps

Issues related to the Pumps

Instrument control panel

Issues related to the Instrument control panel

Versatile valve

Issues related to the Versatile valve

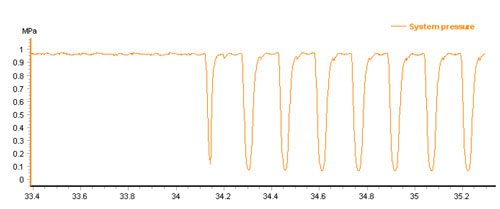

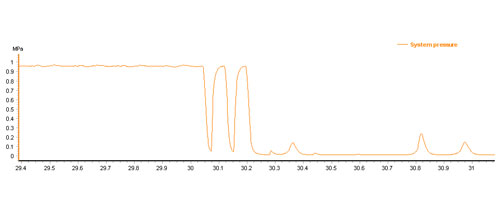

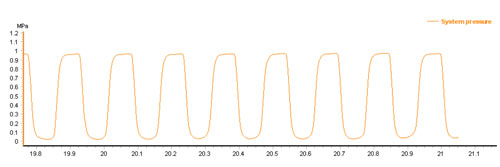

Examples of pump pressure curves

The table below shows some examples of pump system pressure curves obtained when errors have occurred. The examples can be useful in troubleshooting of the System pumps. The System pressure monitor R9 has higher resolution than the other pressure monitors, and is therefore recommended for troubleshooting purposes.

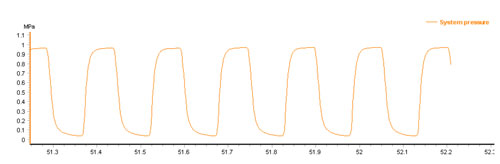

Incident: 30 μl of air enters pump.

Action: Purge pump. See Section 5.4 Prime inlets and purge pump heads, on page 217 in the system handbook.

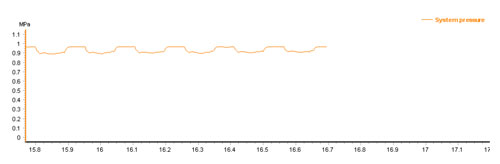

Incident: A large volume of air enters pump.

Action: Purge pump. See Section 5.4 Prime inlets and purge pump heads, on page 217.

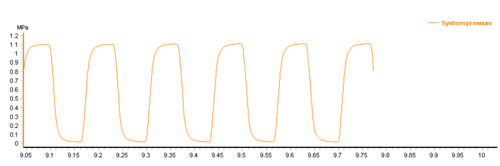

Incident: Blocked outlet check valve

Action: Clean the check valve, See Section 7.6.7 Clean the pump head check valves, on page 343 in the system handbook.

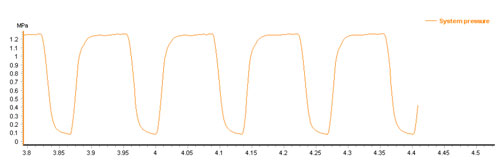

Incident: Inlet check valve is loose.

Action: Tighten the check valve. See Section 7.8.8 Replace the pump head check valves, on page 378 in the system handbook.

Incident: Leaking inlet check valve.

Action: Replace the check valve. See Section 7.8.8 Replace the pump head check valves, on page 378 in the system handbook.

Incident: Leaking outlet check valve.

Actions: Replace the check valve. See Section 7.8.8 Replace the pump head check valves, on page 378 in the system handbook.

Incident: One inlet is blocked,

Action: Clean inlet tubing. For example, perform a System CIP.

Loop valve

Issues related to Loop valve

Inlet valves

Issues related to Inlet valves.

The Inlet valves include Inlet valve A, Inlet valve B and Inlet valve AB.

Fraction collector F9-R

Issues related to Fraction collector F9-R

Injection valve

Issues related to Injection valve

pH monitor and pH valve

Issues related to pH monitor and pH valve

Dummy modules

Issues related to Dummy modules

Column valve

Issues related to Column valve

Fraction collector F9-C

Issues related to Fraction collector F9-C

Method development

Issues related to Method development

General advice to achieve good performance

Before using the system make sure that:

- The correct system has been selected in UNICORN System Control

- The correct wavelength has been set for UV/UPC monitor

- All tubing has been properly connected

- All connectors are free from leakage

- No tubing is folded or twisted

- Online filter, if used, is changed on a regular basis

- Correct buffers are used for the chosen columns and proteins

- All inlet tubing has been immersed in correct buffer solutions

- Enough buffer has been prepared

- Buffers have been equilibrated to the environment temperature

- Buffers/eluents have been degassed if necessary (e.g., in RPC runs)

- Suitable columns have been selected for the target proteins

- Columns have been cleaned and prepared according to column instructions

- Samples have been clarified by centrifugation and/or filtration prior to sample loading

- Samples have been adjusted to binding buffer conditions

- Auto sampler (if used) has been prepared according to user manual

- The fraction collector has been filled with appropriate number of microtiter plates or tubes

- Appropriate arrangement for waste handling has been prepared

UV monitor U9-L

Issues related to UV monitor U9-L

Pressure monitors

Issues related to Pressure monitors

Power and ICU

Issues related to Power and ICU

Conductivity monitor

Issues related to the Conductivity monitor

UV monitor U9-M and UV detector unit

Issues related to UV monitor and UV detector unit

Error codes

All modules

| Error code | Description | Action |

|---|---|---|

| 0 - 19 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

Instrument control unit

| Error code | Description | Action |

|---|---|---|

| 21 - 69 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

Valve

| Error code | Description | Action |

|---|---|---|

| 20, 22, 24 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

| 23 | Faulty air sensor | Restart the instrument. If recurrent please contact Service. |

| 25 | High temperature | See Section 8.3 Troubleshooting: Valves on page 414 in the system handbook. |

Pressure monitor

| Error code | Description | Action |

|---|---|---|

| 20, 21, 24-27 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

| 23 | High temperature | See Pressure monitors, on page 411 in the system handbook. |

Air sensor

| Error code | Description | Action |

|---|---|---|

| 20 | High temperature | See External air sensors, on page 435 in the system handbook. |

Mixer

| Error code | Description | Action |

|---|---|---|

| 25 | Mixer motor error | Restart the instrument. If recurrent please contact Service. |

| 26 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

| 27 | High temperature | See Mixer, on page 431 in the system handbook. |

pH monitor

| Error code | Description | Action |

|---|---|---|

| 20, 21 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

| 25 | No factory calibration | Contact Service |

| 26 | High temperature | See pH monitor and pH valve, on page409 in the system handbook. |

Conductivity monitor

| Error code | Description | Action |

|---|---|---|

| 20-27 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

| 28 | High temperature | See Conductivity monitor, on page 405 in the system handbook. |

| 29 | Temperature data error | Restart the instrument. If recurrent please contact Service. |

| 32-34 | No factory calibration | Contact Service |

Pump

| Error code | Description | Action |

|---|---|---|

| 51-53 | Mixer motor error | Restart the instrument. If recurrent please contact Service. |

| 54 | Internal instrument error | See Section 8.5 Troubleshooting: Pumps, on page 424 in the system handbook. |

UV monitor U9-M

| Error code | Description | Action |

| 21, 25, 26, 31 | Grating error | Restart the instrument. If recurrent please contact Service. |

| 22, 23, 32 | Block filter error | Restart the instrument. If recurrent please contact Service. |

| 24 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

| 27 | Spectrum calibration error | Restart the instrument. If recurrent please contact Service. |

| 28, 29 | Lamp error | Restart the instrument. If recurrent please contact Service. |

| 30 | High temperature | See UV monitor U9-M and UV detector unit, on page 398 in the system handbook. |

UV detector U9-D

| Error code | Description | Action |

|---|---|---|

| 24, 26, 28, 29, 31, 33 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

| 25 | Too low light intensity | Check that the detector and flow cell are fitted correctly. If warning reappears, contact Service. |

| 27 | Too high light intensity | Check that the detector and flow cell are fitted correctly. If warning reappears, contact Service. |

| 30 | Too high light intensity, R channel. | Check that the detector is fitted correctly. If warning reappears, contact Service. |

| 32 | Too high S light intensity, S channel. | Check that the flow cell is fitted correctly. If warning reappears, contact Service. |

| 34 | No light detected | Check optical pathway and restart the instrument. If recurrent please contact Service. |

| 35 | Too low light intensity, R channel. | Check that the detector is fitted correctly. If warning reappears, contact Service. |

| 36 | Too low light intensity, S channel. | No light through flow cell. Check solution absorption and that the cell is fitted correctly. |

UV monitor U9-L

| Error code | Description | Action |

| 51 | High temperature | See UV monitor U9-L, on page 403 in the system handbook. |

| 52, 55 | Low lamp intensity | Contact Service |

| 54 | Autozero out of range | Autozero requested when AU value is larger than 2. |

| 58 | Too low light intensity, S channel. | No light through flow cell. Check solution absorption and that the cell is fitted correctly. |

| 59, 60 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

| 61 | Measurement error | Restart the instrument. If recurrent please contact Service. |

Fraction collector F9-R

| Error code | Description | Action |

|---|---|---|

| 20 | High temperature | See Section 8.4 Troubleshooting: Fraction collector, on page 422 in the system handbook. |

| 21 | Drop sync warning | Clean the sensor and remove air bubbles in the flow path. |

| 22 | Tube sensor error | Check that the tube sensor is adjusted properly. |

| 23 | Delay queue full | Increase the fraction size. Fraction size must be greater than 1/10 of the delay volume. |

| 24, 26 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

| 25, 28 | Too fast tube change | Increase the fraction size or lower the flow rate. |

| 27 | Drop sync error | Clean the drop sensor |

Instrument control panel

| Error code | Description | Action |

|---|---|---|

| 51 | High temperature | See Instrument control panel, on page 437 in the system handbook. |

I/O-box

| Error code | Description | Action |

|---|---|---|

| 20 | High temperature | See section "Troubleshooting" |

| 21 | Analog in signal below -2V | Check the external equipment connected to the I/O-box. |

| 22 | Analog in signal above 2V | Check the external equipment connected to the I/O-box. |

| 23-28 | Internal instrument error | Restart the instrument. If recurrent please contact Service. |

External air sensors

Issues related to External air sensors

pH valve

Issues related to pH valve

Source: https://www.cytivalifesciences.com/en/us/support/products/akta-pure-25-l1-29018225

0 Response to "Akta Pure 25 Error in Order to Continue the Filled Tubes Have to Be Replaced"

Post a Comment